The Best Guide To Harvest Right Freeze Dryer

Wiki Article

Harvest Right Freeze Dryer - An Overview

Table of ContentsThe Basic Principles Of Harvest Right Freeze Dryer How Harvest Right Freeze Dryer can Save You Time, Stress, and Money.The Main Principles Of Harvest Right Freeze Dryer What Does Harvest Right Freeze Dryer Do?How Harvest Right Freeze Dryer can Save You Time, Stress, and Money.How Harvest Right Freeze Dryer can Save You Time, Stress, and Money.

There are three stages in the lyophilization procedure: Pre-freezing, main drying, and secondary drying out. The pre-freezing stage is one of the most essential phase of the freeze-drying process. In this phase, sample material will need to be cooled to at the very least the temperature level of the melting point for that example. This guarantees the example will be entirely frozen as well as can then undertake sublimation.The rate at which your example freezes will certainly impact the dimension of the ice crystals that develop. Otherwise done appropriately, it can impact the rate of reconstitution, size of the freeze-drying procedure and stability and security of your example. Larger ice crystals help with faster and also a lot more effective lyophilization because water molecules are able to relocate extra easily out of the example during sublimation.

The Buzz on Harvest Right Freeze Dryer

Added warmth is included this phase to repel excess moisture, leaving behind a moisture material of regarding 2%. Second drying is commonly used in samples that are being planned for long term conservation and storage space. While freeze drying can accomplish many things, its key objective is to safeguard the biological as well as chemical framework of an example through the procedure of sublimation.Busy, the applications of freeze drying are infinite.

What Does Harvest Right Freeze Dryer Do?

Freeze drying is simplest to accomplish using large ice crystals, which can be generated by slow-moving freezing or annealing. With organic products, when crystals are too huge they might damage the cell walls, and that leads to less-than-ideal freeze drying out results.

Concerning 95% of the water in the material is gotten rid of in this phase. Key drying can be a slow-moving procedure. Way too much warmth can change the structure of the product. Freeze drying out's last phase is second drying (adsorption), throughout which the ionically-bound water particles are removed. By basics elevating the temperature more than in the key drying out phase, the bonds are broken in between the material and the water particles.

The Basic Principles Of Harvest Right Freeze Dryer

After the freeze drying process is full, the vacuum cleaner can be braked with an inert gas prior to the material is secured. A lot of products can be dried out to 1-5% residual dampness.Freeze-drying or lyophilization is a dehydration method based on the sublimation of water in an item (, ). This implies that the product's water material shifts from a strong to a gaseous state or from ice to vapor without undergoing the fluid state (). Freeze-drying is taken into consideration a premium quality dehydration method for a number of factors, consisting of (, ): it runs at reduced temperatures, which adds to maintaining a product's dietary worth, preference, appearance, and also heat-sensitive compoundsfreezing prevents chemical and microbiological processes, which substantially delays the product's damage (thus expanding its service life) Raw foods are included regarding 80%95% water, which can be separated into "totally free" and also "bound" water.

In the freeze-drying process, all cost-free water as well as some bound water must be removed, and also free water should stay icy in all times. This is the main difference in between freeze- as well as vacuum-drying and also the most difficult action (). The freeze-drying process can be divided right into three actions (,, ): The product is commonly iced up under air pressure.

Little Known Questions About Harvest Right Freeze Dryer.

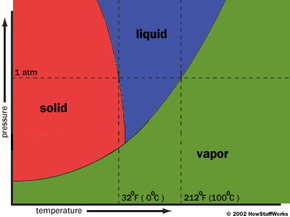

Likewise called desorption drying, it's the drying of items to their desired humidity by removing the continuing to be bound water. Freeze-drying need to be carried out in regulated problems that do not melt the water, seeing that the visibility of liquid water may transform the check my site product's composition, shape, as well as physical homes ().The basic principle in suspended animation is sublimation, the change from a solid straight right into a gas. Much like dissipation, sublimation occurs when a particle gains sufficient energy to break cost-free from the particles around it. Water will superb from a solid (ice) to a gas (vapor) when the molecules have enough power to damage cost-free yet the conditions aren't right for a fluid to develop. Harvest Right freeze dryer.

For a compound to take any certain stage, the temperature as well as pressure must be within a certain variety. Without these problems, that stage of the material can't exist. The chart listed below shows the necessary stress and also temperature level values of different phases of water. You can see from the graph that water can take a fluid kind at sea level (where pressure amounts to 1 atm) if the temperature is in between the sea level cold point (32 levels Fahrenheit or 0 levels click now Celsius) and also the sea degree boiling point (212 F or 100 C).

All about Harvest Right Freeze Dryer

06 environments (ATM MACHINE), the water is cozy sufficient to thaw, yet there isn't enough stress for a liquid to create. It ends up being a gas. This is exactly what a freeze-drying equipment does. A regular maker contains a freeze-drying chamber with numerous shelves affixed to heating units, a freezing coil connected to a fridge compressor, and also an air pump.Report this wiki page